If you look closely around you, you may notice that there are tubes and pipes in different materials, shapes and sizes everywhere. Tubing fabricated with T-DRILL machine tools can be found under the bonnet of both Ford and Mercedes cars, in Toshiba switchgear and even in the famous CERN particle accelerator.

T-DRILL pipes and tubes carry Coca-Cola, diesel oil, anti-freeze, medicine, milk, waste water, gases… In fact, they may even have been to the moon.

In July 27, 2012 the whole world watched the spectacular opening ceremony of the Olympic Games in London. One of its highlights was the Olympic flame. T-DRILL is proud to be a part of that engineering wonder: There were 204 extruded branches in the cauldron that were made by using T-DRILL 60 SS pipe branching machine.

Who was trusted to build the iconic Olympic cauldron was a well-kept secret. Now we know that the job was done by Waites Mechanical Services, a packaged plant and pipe manufacturer in Batley, England. At that time we at T-DRILL had no idea of being a part of the great success of the ceremony.

”I will not forget the feeling of seeing our work at the centre of the Olympic ceremonies. I’m really pleased we were chosen to represent the best in British Industry, a tribute to West Yorkshire craftsmanship and rightfully proud of our achievements” says Mr. Ian Waites, Director of WMS in a Press Release published by Stage One, UK.

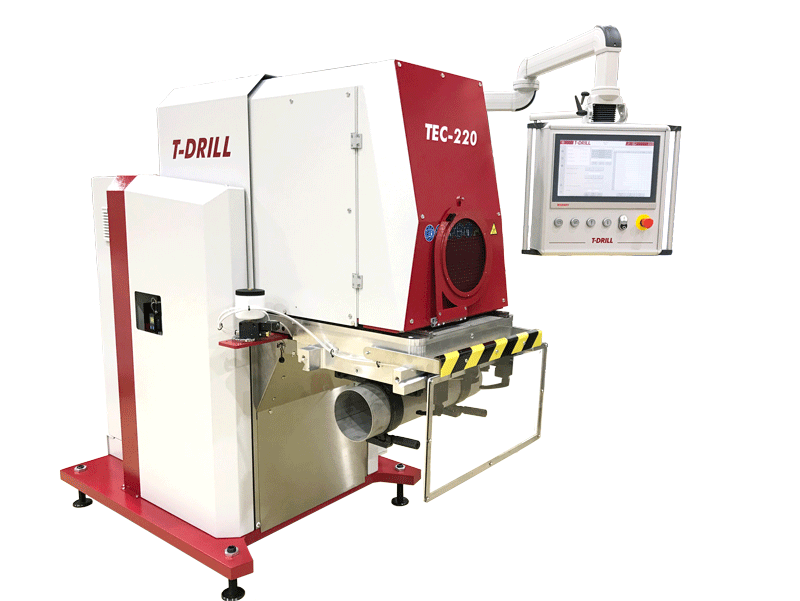

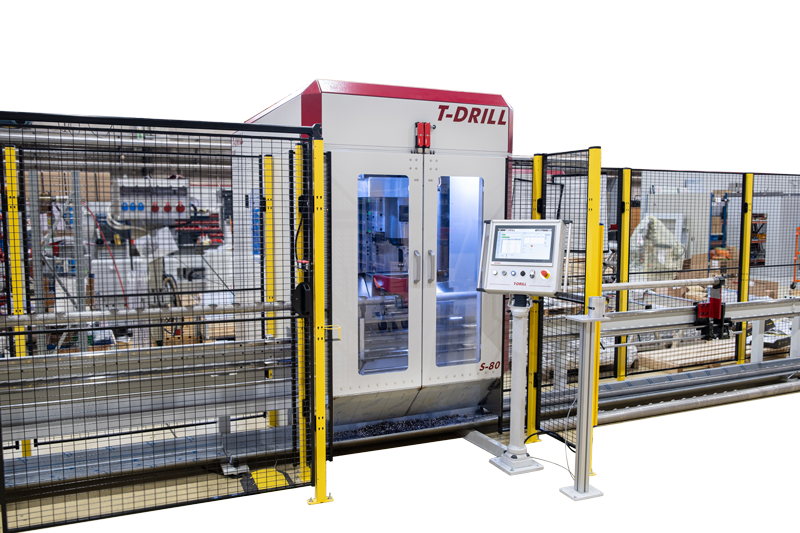

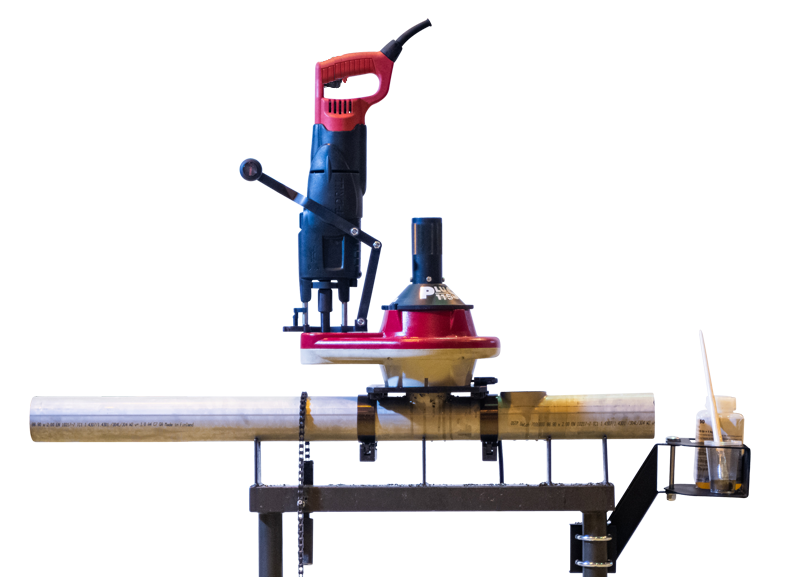

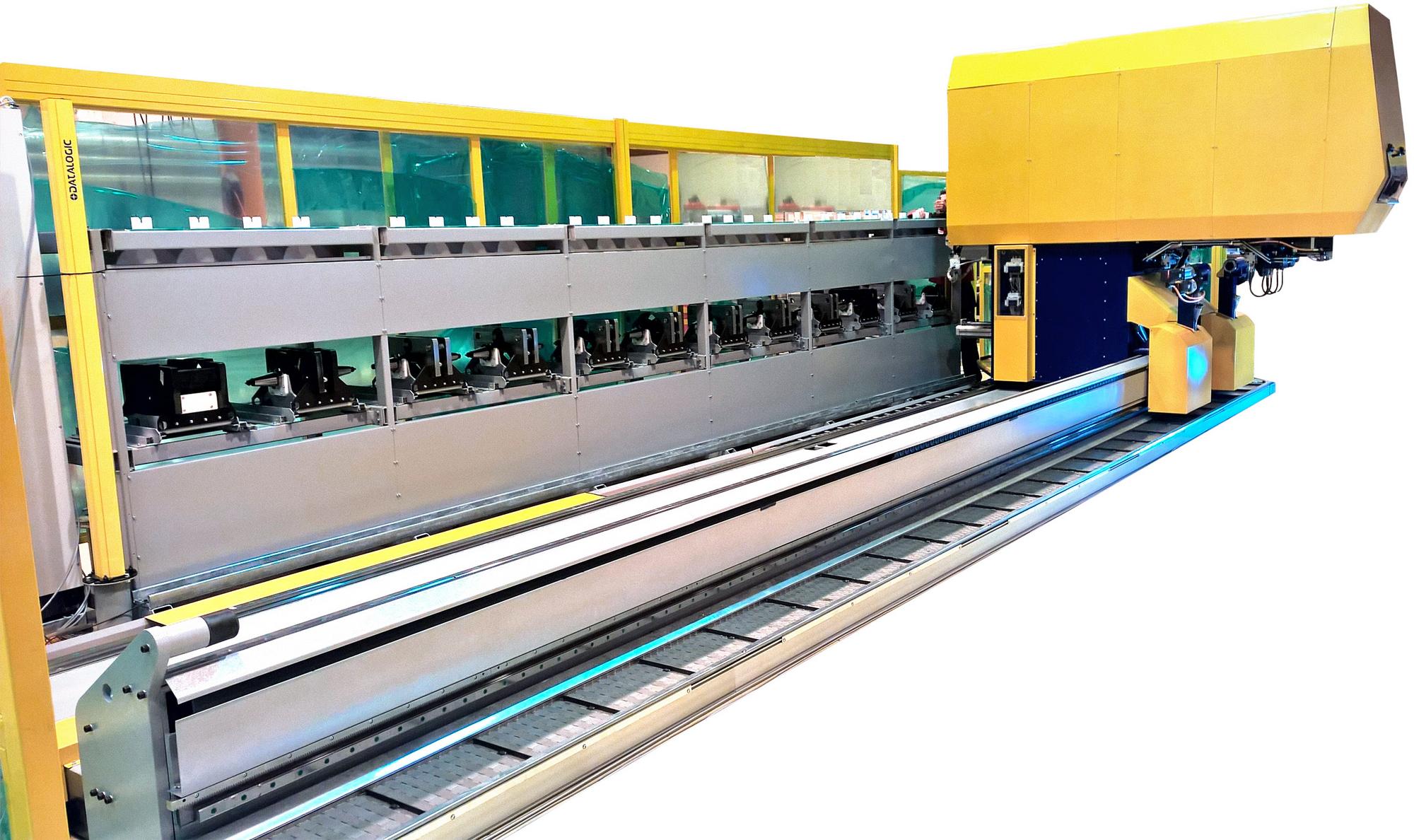

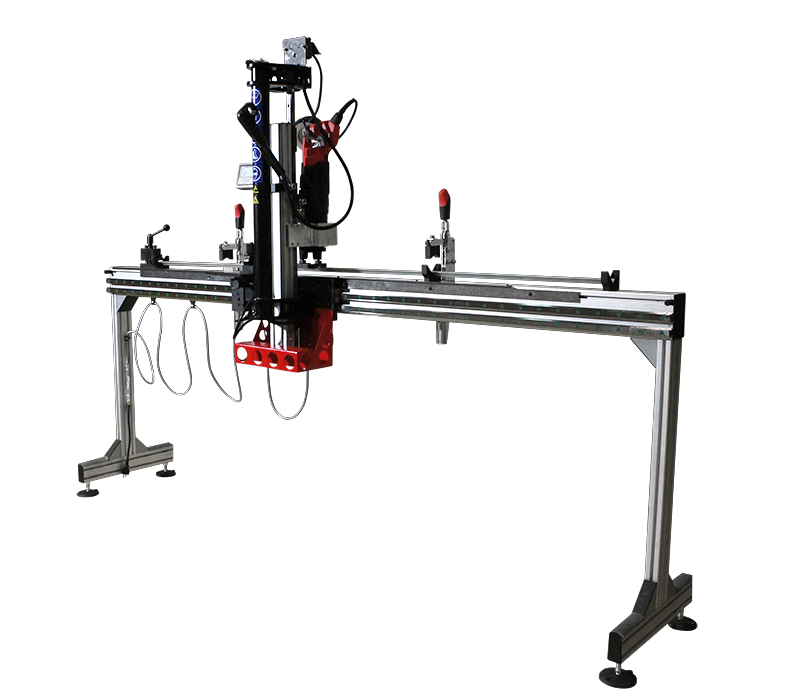

The modular design of T-DRILL machines and equipment allows us to meet industry specific requirements and offer optimized tube and pipe manufacturing solutions. Stand-alone machines can be integrated to Flexible Manufacturing Systems that are able to produce various type of products.

As an example of integrated cutting, branching and tube end forming, the systems in the attached photo produce manifolds for floor heating systems.

Contact our Sales and we will help you to find the best solutions also for your tube and pipe manipulation requirements.

Most commonly used technologies:

Share on social media